I can hear it now. "You drive a truck, It's loud , get used to it." Well, it is a deisel truck but it doesn't have to be loud. On long trips, loud can get to you so I decided to see what I could do about making the cab quieter. I did some research on sound damping materials and found some made by Second Skin. It's a good product that is cheaper than the Dynamat that everyone hears about.

I bought 40 sq feet of Damping Mat and 18 sq ft of acoustical foam. The damping mat comes in 2 sq ft sheets and is an aluminum skin over a rubber compound with an adhesive backing. Be careful handling the sheets as the aluminum skin is sharp and can easily cut you. I recommend wearing latex gloves while handling it to protect your hands and to keep the adhesive from sticking to you. (It really sticks well to hair)

I did this install on a 06 Quad Cab Cummins but the principals hold for any vehicle.

NOTE: I highly recommend you get and look through the Service Manual for your year truck, it will go into great detail on how to install/uninstall the seats and belts. Please ensure you reinstall seats and all safety equipment per specs listed in the manual.

Vibration Damping sheets and Acoustical foam

Remove Seats and Seat belts

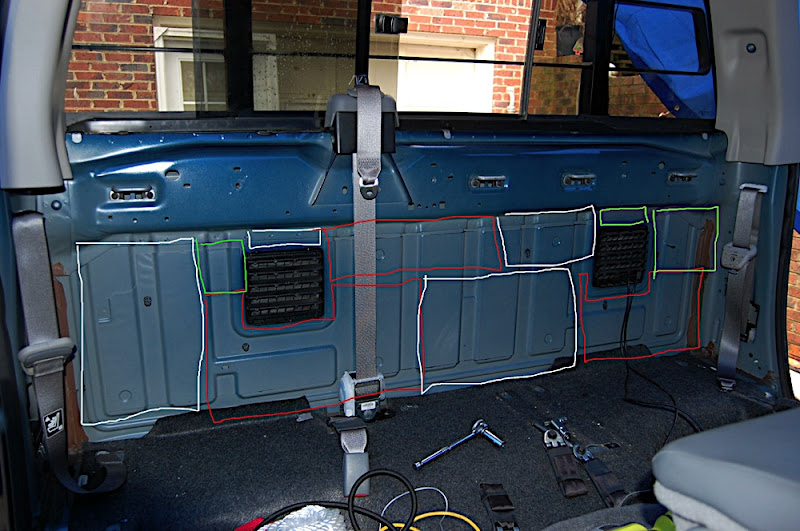

Remove Seats and Seat beltsWe will start the install on the back cab wall as this is a very easy way to get the hang of it. This will be much easer than the doors as you can work with full sheets.

Unbolt and remove the seats then unbolt the seatbelts, once those are out you can remove the plastic side panels. These panels hold the carpet and factory panels in place.

Remove the fiber sound deadening panel

Remove the fiber sound deadening panelUnbolt the 3 belts across the top of the panel, the seat belt retractor and the plastic clips (2 grey and 3 black). Once these are removed, the panel pulls away from the cab wall.

Clean Surface

Clean SurfaceClean the metal with a glass cleaner to remove dirt any oils or grease. This gives the mat a good surface on which to adhere. Grab a few damping sheets and start leaning them against the wall to give you some idea of how many you will need. If you are good at jigsaw puzzles this will be easy for you.

It is important to note that you do NOT need to cover every exposed surface completely. Just placing mat on a portion of the metal increases its effective mass and helps absorb vibrations.

Here is a mockup of how you might put the sheets on. It is not to scale but shows about 4-5 sheets were used. (I think I used about 9 sq feet of material including bits a pieces)

Trimmed sheet

Trimmed sheetI trimmed a sheet (with a razor knife) to fit around the cab vent. You dont need to get the measurements accurate to the inch. You will also want to make sure you don't cover up any screw holes or fastener openings. Keep any pieces you cut as they can be used in the "odd" areas where full sheets don't fit.

Close up of the cab vent. (I ran my Ham radio antenna coax through here)

If you look closely you can see where I reused bits of matting around the vent. (It really is a jigsaw puzzle)

When you place the damping material on the metal you will need follow the contours of the metal so place the mat on the metal on one side and press it into the contours of the metal. Here you can see the contours of the panel and the mat following the contours. I pressed the matting to the metal with my fimgers but they make small wooden rollers that may make it easier to do.

This is the finished cab and the floor. It took me about 45 minutes to do this (not including removing and reinstalling the seats and panels)

Cab Doors

Cab DoorsWhen working on the cab doors you dont have full access to the panel and will need to cut the sheets down to manageable pieces. For the front doors you can use larger pieces but the rear doors have much smaller openings and will need smaller cut sheets.

This is the raw door surface.

I used a full sheet of material (cut in 4 pieces) in the bottom of the door. I used half a sheet above the structural cross member at the top of the picture. Once that was complete, i covered the mat with the acoustical foam.

Cut foam strips

Cut foam stripsSpray the foam strips on one side with 3M glue. (I got a high strength spray glue at home depot)

Use the same glue and spray a small section of the door panel. Wait about 45 seconds for the glue to get tacky and then place the foam against the panel. Once the foam is in place tap it down and work on the next piece. I only covered the areas where I originally put the damping material.

Rear Door

Rear DoorThe openings on the rear doors are much smaller and the panel much less accessible than the front doors. You will need to cut smaller sheets to do these. I'm not going to go into a lot of detail as it is much of the same. Cut, Peal, stick, spray, etc

Closeup of panel

Finished install

I didn't show pictures but I also added the damping mat and foam to the upper panels of the doors.

What does it all mean?So the 100 dollar question? Did it work? I didnt take scientific measurements but I have noticed a marked improvement.

1. When driving, the most noticeable sound is the engine. Almost all the sounds I hear now come from the front of the engine compartment.

2. Unless I really listen (with my foot off the skinny pedal) it is very hard to hear road noise.

3. I cant hear my tires unless I roll down the window. (Don't know how much less you would hear an aggressive mud tire)

4. The stereo is a lot clearer and louder than it was before.

I also made a point of driving beside a number loud diesels (7.3 ford, 24 valve Cummins) on the highway and pulling up beside them at stop lights.

I could only hear them if they were on the drivers side (and that was muffled). When they are on the passengers side I couldn't hear them over my engine.

Im very pleased and think it was well worth the effort to do this. All total I spent about 4-5 hours on the install from start to finish. (Hard to say as I was also in the middle of another DIY)

For the purists out there, Yes, I still roll down my window to hear the engine rattle and turbo sing. It is still and always will be a sweet sound.